Selecting the Right Spring Check Valve for Your System

2025-10-10

Spring check valves are an essential component in fluid control systems, designed to allow fluid to flow in one direction while preventing backflow. These valves operate automatically and are widely used in water supply systems, industrial pipelines, HVAC systems, and various process applications. By combining simplicity with reliable performance, spring check valves provide efficient control of liquid or gas flow in many settings.

The primary function of a spring check valve is to maintain unidirectional flow. Unlike manual valves, which require user operation, spring check valves use an internal spring to keep the valve closed when flow stops or reverses. When fluid pressure exceeds the spring force, the valve opens, allowing flow in the intended direction. Once pressure drops or backflow occurs, the spring pushes the valve back to the closed position, preventing reverse flow and protecting equipment downstream.

One of the main advantages of spring check valves is their automatic operation. This feature ensures reliable performance even in systems where manual monitoring is impractical. The spring mechanism allows for quick response to changes in flow, small the risk of damage from backflow or water hammer. These valves are particularly useful in pumps, pipelines, and storage tanks, where preventing reverse flow is critical to maintaining system efficiency and safety.

Spring check valves are available in a variety of materials, including stainless steel, brass, bronze, and cast iron. Material selection depends on the fluid type, temperature, and pressure in the system. Stainless steel valves are often chosen for corrosion resistance and durability in industrial applications, while brass or bronze valves are commonly used in water supply systems. Proper material selection ensures long-term reliability and reduces the need for frequent maintenance.

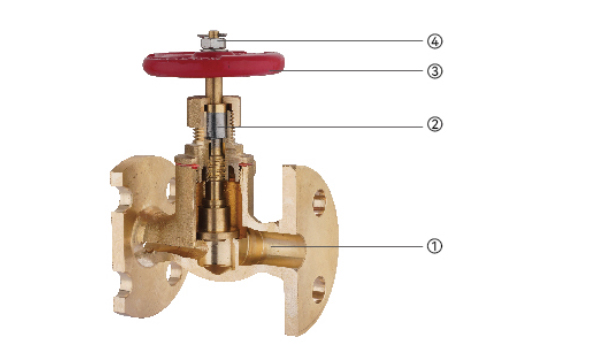

The design of spring check valves allows them to function in both vertical and horizontal installations. Their compact structure makes them suitable for spaces where larger or more complex valves may not fit. Many valves feature threaded, flanged, or welded connections, providing flexibility in installation and integration with existing piping systems. Flow capacity and pressure rating should be matched to system requirements to ensure good performance.

Maintenance of spring check valves is relatively straightforward. Periodic inspection and cleaning of the internal components, such as the spring and seat, help prevent buildup, corrosion, or wear that could affect operation. Replacement of worn springs or seals ensures continued reliable performance. Because these valves operate automatically, proper maintenance is essential to prevent failure that could compromise system safety or efficiency.

Spring check valves are used in a wide range of applications. In water systems, they prevent reverse flow in pumps, pipelines, and storage tanks. In industrial processes, they protect equipment such as compressors, heat exchangers, and chemical reactors from backflow. In HVAC systems, they maintain unidirectional flow in heating and cooling circuits. Their versatility, compact size, and reliable operation make them suitable for many fluid control scenarios.

Overall, spring check valves provide an effective and reliable solution for preventing backflow in liquid and gas systems. Their automatic operation, durable construction, and versatility in installation make them a key component in industrial, commercial, and domestic applications. By selecting the right valve type and material and performing regular maintenance, system operators can ensure long-term performance and protection against reverse flow.

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally.

русский

русский Español

Español عربى

عربى