Valve Technology Advances: Enhancing Fluid Control Across Industries

2025-07-11

Valves are the backbone of fluid control systems, regulating the flow, pressure, and direction of liquids and gases across countless applications. From simple household faucets to complex industrial processing plants, valves like ball valves, faucets, angle valves, stop valves, check valves, and valve joints play essential roles in maintaining system integrity, safety, and efficiency.

With technological innovation and stricter industry standards driving demand for smarter, more reliable components, the valve sector is experiencing significant advancements.

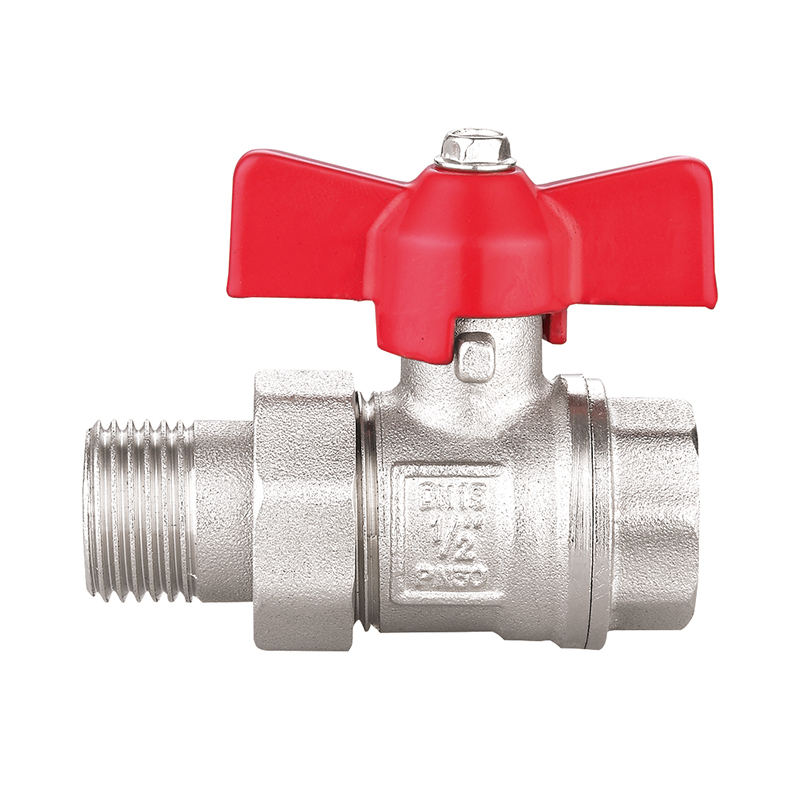

Ball Valves: Precision and Durability in Flow Control

Ball valves are prized for their simple quarter-turn operation and tight sealing capabilities. Featuring a spherical ball with a drilled hole, these valves offer pressure drop and fast on/off control. Their versatility spans industries including oil and gas, water treatment, pharmaceuticals, and HVAC.

Recent innovations focus on enhancing material durability with stainless steel, brass, and high-performance plastics to resist corrosion and wear. Additionally, automated ball valves equipped with electric or pneumatic actuators allow remote operation and integration into smart control systems, supporting the rise of Industry 4.0 and digital infrastructure.

Faucets: Everyday Reliability with Increasing Sophistication

While faucets are ubiquitous in residential and commercial plumbing, their design has evolved beyond basic water delivery fixtures. Modern faucets incorporate water-saving aerators, anti-scald technology, and sensor-based touchless controls that promote hygiene and conserve resources.

Smart faucets with connectivity features enable remote monitoring of water usage and leak detection, aligning with global efforts to reduce water wastage. Manufacturers are also innovating with sustainable materials and finishes that resist corrosion and provide long-lasting aesthetics.

Angle Valves: Compact Solutions for Precise Flow Management

Angle valves are often installed where space constraints exist, offering a 90-degree change in flow direction and fine control via manual handles or knobs. Commonly used in plumbing systems to regulate water supply to fixtures, they are also found in industrial applications requiring localized flow adjustments.

Material advances and ergonomic designs are enhancing angle valve performance and ease of installation. Furthermore, the integration of durable sealing technologies ensures leak-proof operation under variable pressure conditions.

Stop Valves: Essential for Safety and Maintenance

Stop valves provide critical shutoff functions, allowing sections of piping or equipment to be isolated for maintenance or emergencies. Their reliable closure mechanisms, which can be gate, globe, or ball types, are designed to withstand repeated operation without leakage.

The industry is moving toward stop valves with enhanced corrosion resistance, longer service life, and compatibility with a broader range of fluids, including aggressive chemicals. Automation options also facilitate remote isolation in hazardous or hard-to-access areas, improving safety protocols.

Check Valves: Preventing Backflow and Protecting Systems

Check valves allow fluid to flow in one direction while preventing reverse flow, safeguarding pumps, compressors, and pipelines from damage. Variants include swing check, lift check, ball check, and spring check valves—each tailored for specific operational parameters.

Advances in check valve designs aim to reduce water hammer effects and noise, improve sealing under low-pressure conditions, and support maintenance-friendly configurations. Material enhancements ensure reliable performance in corrosive or high-temperature environments.

Valve Joints: Ensuring Secure and Flexible Connections

Valve joints, including unions, couplings, and flanges, are vital for connecting valves to pipelines securely while permitting disassembly for maintenance or replacement. Their designs accommodate different pipe materials and sizes, with options for threaded, welded, or gasket-sealed connections.

Recent developments focus on quick-connect systems and corrosion-resistant coatings that simplify installation and extend service life. Compatibility with automated valve systems also supports seamless integration within complex piping networks.

Market Dynamics and Technological Trends

The global valve market continues to expand, fueled by infrastructure development, industrial automation, and stringent environmental regulations. Demand for valves with enhanced durability, precision, and smart capabilities is rising across sectors such as oil and gas, water and wastewater management, chemical processing, and construction.

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally.

русский

русский Español

Español عربى

عربى