Brass Ball Valves Gain Momentum Across Industries for Durability and Operational Efficiency

2025-07-11

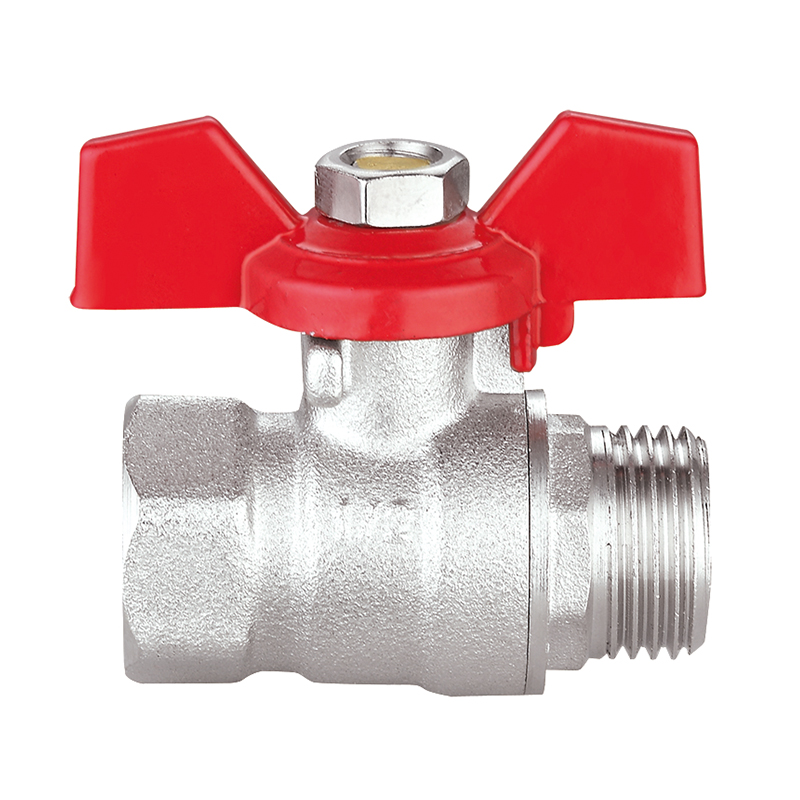

In the ever-evolving world of industrial fluid control, the demand for components that can withstand harsh environments while ensuring smooth and precise operation continues to rise. Among the range of valve types available, brass ball valves are emerging as a solution across numerous sectors. Known for their corrosion resistance, ease of operation, and broad compatibility with various media, brass ball valves are becoming an integral part of plumbing, HVAC, manufacturing, agriculture, and even marine systems.

Market Growth Driven by Multi-Sector Applications

Recent market analyses show a marked increase in the adoption of brass ball valves, primarily driven by their cost-effectiveness and long service life. The global industrial valves market is expected to surpass USD 100 billion by 2030, and brass ball valves constitute a significant portion of this growth. Their applicability across both residential and industrial sectors provides a unique edge over other valve materials that may only be suitable for niche functions.

In residential plumbing, brass ball valves are widely used for controlling water flow due to their resistance to mineral buildup and corrosion from chlorinated water. Their ability to maintain integrity under both hot and cold conditions makes them ideal for home heating systems and domestic water lines. On the other hand, industries leverage brass ball valves for handling fuels, oils, air, and non-corrosive gases due to their mechanical strength and leak-proof shutoff design.

Design and Operational Advantages

Brass ball valves are designed with a spherical closure unit that rotates within the valve body, allowing for quarter-turn operation. This simple yet highly effective mechanism enables fast shutoff and reliable flow control, even in high-cycle applications. The smooth interior finish and unobstructed bore reduce flow resistance, improving energy efficiency in fluid handling systems.

Additionally, many brass ball valves feature a blowout-proof stem and double O-ring seals that enhance safety and performance, especially in pressurized systems. Their manual or automated actuation options further support integration into both traditional and smart pipeline infrastructures.

Corrosion Resistance and Material Benefits

Unlike steel, which is prone to rust, or plastics that can warp under pressure or heat, brass provides a robust balance of strength and corrosion resistance. This makes it particularly suitable for environments where exposure to water, oil, and mild chemicals is constant. Brass is also more resistant to dezincification than other copper alloys, which prolongs the valve’s operational life.

Furthermore, brass is known for its machinability, allowing manufacturers to produce valves with precise tolerances and customized port sizes. This versatility in design contributes to reduced leakage risks and improved fitting within complex piping layouts.

Compactness and Versatile Integration

The compact form factor of brass ball valves allows them to be installed in tight or confined spaces, such as within wall cavities or compact machinery. This makes them highly sought after in industries where space-saving is critical—such as automotive systems, marine vessels, and mobile units. Their threaded, flanged, or sweat connections also facilitate easy integration into existing pipelines without extensive modifications.

Sustainability and Environmental Considerations

With increasing global emphasis on sustainability and energy conservation, brass ball valves also score high on recyclability. Brass is a material that can be reprocessed with loss in quality, contributing to circular manufacturing practices. In water conservation projects, brass ball valves serve as crucial components in drip irrigation systems, greywater recycling units, and rainwater harvesting systems.

Moreover, advancements in lead-free brass alloys have opened up new opportunities for compliance with stringent environmental regulations, especially in potable water systems. These innovations ensure that brass ball valves remain both an environmentally and health-conscious choice for a wide range of applications.

Challenges and Innovations

While brass ball valves offer numerous advantages, certain limitations such as their unsuitability for highly acidic or alkaline media have prompted ongoing research. Manufacturers are now introducing hybrid brass valves with internal linings or coatings that increase their compatibility with aggressive chemicals. Additionally, smart valve variants equipped with sensors and IoT connectivity are being developed to provide real-time performance data, making predictive maintenance more accessible.

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally.

русский

русский Español

Español عربى

عربى