Globe Valves Manufacturers

Globe valves are widely used in various industrial and residential applications for their ability to regulate fluid flow with precision. These valves feature a spherical body with an internal baffle that divides the flow path, allowing for efficient throttling and control. The design of globe valves includes a movable disc or plug that seats against a stationary ring, providing a tight seal when closed. This configuration enables globe valves to handle high-pressure and high-temperature conditions, making them suitable for demanding environments. They are commonly used in steam, water, and oil systems, where precise flow control is essential. The linear motion of the disc or plug in globe valves allows for fine adjustments, making them ideal for applications requiring gradual flow modulation. Globe valves are also known for their durability and long service life, with minimal maintenance requirements. Regular inspection and lubrication of the valve components ensure optimal performance and prevent potential issues. The versatility and reliability of globe valves make them a preferred choice for engineers and technicians in various industries.

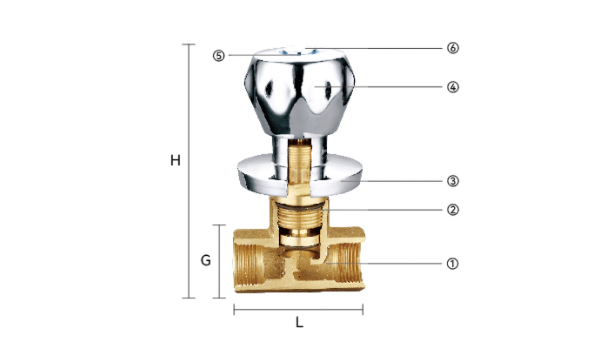

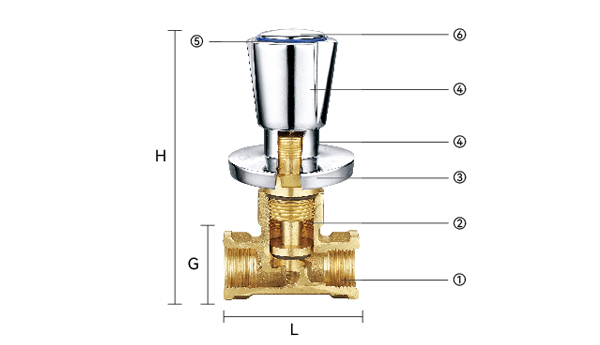

XFM-0501 Brass Concealed Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Cartridge | Brass |

| 3 | Rosette | Zinc |

| 4 | Handle | Zinc |

| 5 | Red&Blue Screw | PE |

| 6 | Logo Cover | ABS |

| G | L | H |

| 1/2" | 58 | 113 |

| 3/4" | 67 | 125 |

| 1" | 69 | 128 |

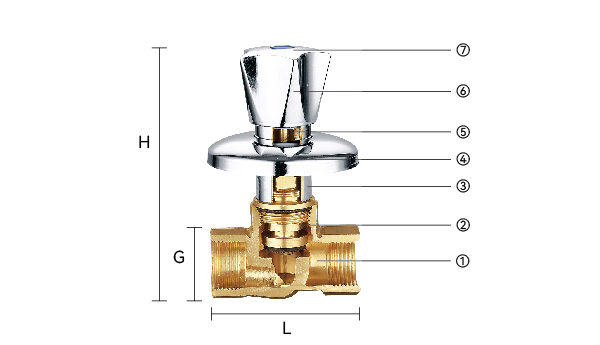

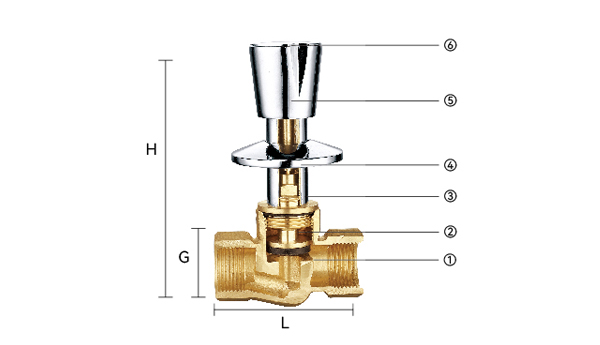

XFM-0502 Brass Concealed Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Cartridge | Brass |

| 3 | Pipe | Brass/Zinc |

| 4 | Rosette | Brass/Stainless Steel |

| 5 | Cap | POM |

| 6 | Handle | Zinc |

| 7 | Red&Blue Screw | PE |

| G | L | H |

| 1/2" | 57 | 109 |

| 3/4" | 69 | 117 |

| 1" | 75 | 130 |

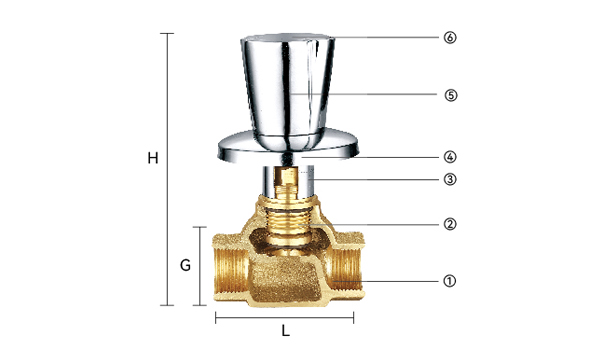

XFM-0503 Brass Concealed Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Cartridge | Brass |

| 3 | Pipe | Brass |

| 4 | Rosette | Brass |

| 5 | Handle | Zinc |

| 6 | Logo Cover | ABS |

| G | L | H |

| 1/2" | 52 | 115 |

| 3/4" | 76 | 136 |

| 1" | 88 | 147 |

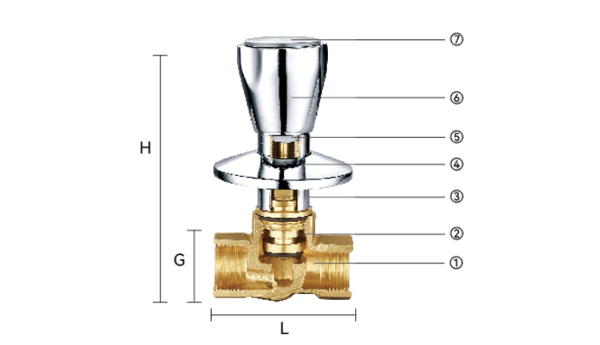

XFM-0505 Brass Concealed Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Cartridge | Brass |

| 3 | Pipe | Brass/Zinc |

| 4 | Rosette | Brass/Steel |

| 5 | Cap | POM |

| 6 | Handle | Zinc |

| 7 | Logo Cover | ABS |

| G | L | H |

| 1/2 | 57 | 124 |

| 3/4 | 69 | 132 |

| 1 | 75 | 145 |

XFM-0506 Brass Concealed Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Cartridge | Brass |

| 3 | Rosette | Steel |

| 4 | Pipe | Zinc |

| 5 | Handle | Zinc |

| 6 | Red&Blue Screw | PE |

| 7 | Logo Cover | ABS |

| G | L | H |

| 1/2 | 65 | 131 |

| 3/4 | 68 | 135 |

XFM-0507 Brass Concealed Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Cartridge | Brass |

| 3 | Pipe | Brass/Zinc |

| 4 | Rosette | Brass/Steel |

| 5 | Handle | Zinc |

| 6 | Logo Cover | ABS |

| G | L | H |

| 1/2 | 57 | 138 |

| 3/4 | 67 | 145 |

| 1 | 93 | 170 |

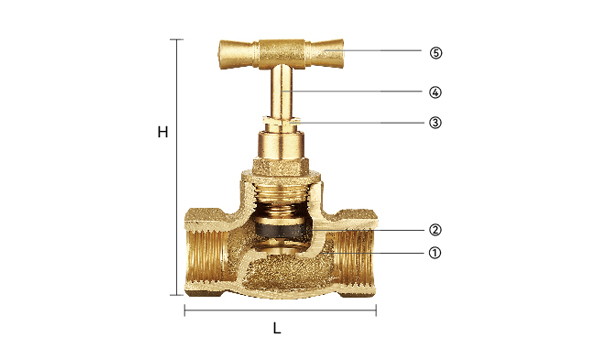

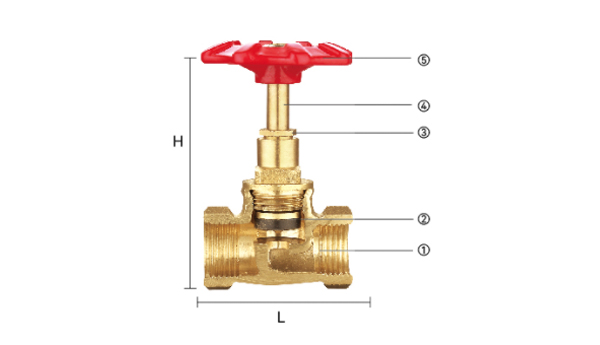

XFM-0508 Brass Water Stop Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Seal Ring | NBR |

| 3 | Lock Nut | Brass |

| 4 | Stem | Brass |

| 5 | Handle | Brass |

| G | L | H |

| 1/2 | 60 | 85 |

| 3/4 | 65 | 89 |

| 1 | 74 | 98 |

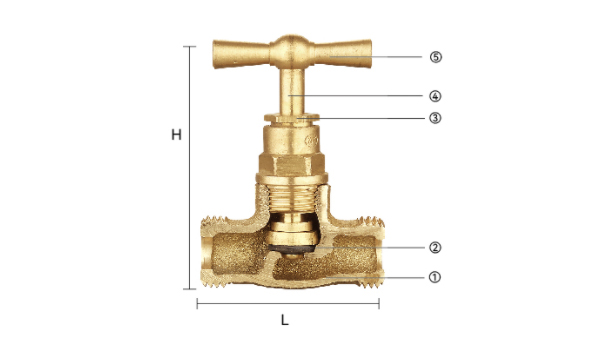

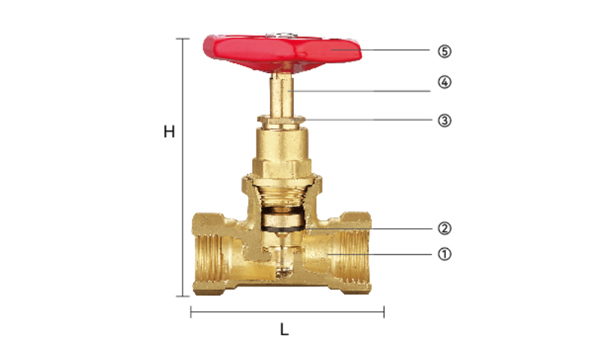

XFM-0509 Brass Water Stop Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Seal Ring | NBR |

| 3 | Lock Nut | Brass |

| 4 | Stem | Brass |

| 5 | Handle | Brass |

| G | L | H |

| 1/2 | 52 | 75 |

| 3/4 | 57 | 82 |

XFM-0510 Brass Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Seal Ring | NBR |

| 3 | Lock Nut | Brass |

| 4 | Stem | Brass |

| 5 | Handle | Iron |

| G | L | H | A |

| 1/2 | 52 | 85 | 54 |

XFM-0511 Brass Globe Valve

| Description | Raw Material | |

| 1 | Body | Brass |

| 2 | Seal Ring | NBR |

| 3 | Lock Nut | Brass |

| 4 | Stem | Brass |

| 5 | Handle | lron |

| G | L | H | A |

| 1/2 | 58 | 82 | 48 |

XFM-0512 Brass Globe Valve

XFM-0515 Angle Globe Valve

-

Globe valves are a fundamental component in fluid control systems, used across industries such as energy, water treatment, and manufacturing. Their design, which incorporates a movable plug or disc, a...

READ MORE -

The polished angle valve sector has attracted growing attention due to increased demand from plumbing, heating, and industrial fluid systems. Polished angle valves serve as key components for controll...

READ MORE -

Production Capabilities and Material Expertise Polished bibcocks are essential fixtures in plumbing systems, providing controlled water flow in residential, commercial, and industrial applications. Po...

READ MORE -

Industry Importance and Demand Foot valves are essential components in pumping systems, preventing backflow and maintaining prime in suction lines. Foot valve manufacturers play a critical role in sup...

READ MORE -

Float valves are essential components used in a variety of industries to regulate the level of liquids in tanks, reservoirs, and other containers. They are designed to automatically control fluid leve...

READ MORE -

Swing check valves are essential components used in fluid control systems to ensure that fluid flows in only one direction. These valves play a critical role in preventing backflow, protecting equipme...

READ MORE -

What Are Spring Check Valves? Spring check valves are mechanical devices that allow fluid to flow in only one direction. Equipped with a spring-loaded mechanism, these valves automatically close when ...

READ MORE -

Bibcocks are essential components used to control the flow of water. To ensure long-lasting performance and resistance to corrosion, many bibcocks are coated with a layer of chrome. This chrome platin...

READ MORE -

Brass ball valves have become an essential component in numerous applications, from plumbing and heating systems to chemical processing and water distribution. Brass, known for its durability, corrosi...

READ MORE -

The Polished Angle Valve Factory plays a key role in the production of high-quality plumbing valves designed for both functional performance and visual appeal. These polished angle valves are widely u...

READ MORE -

What Does a Polished Bibcock Factory Produce? A polished bibcock is a type of wall-mounted tap commonly used for outdoor, utility, or residential purposes. Designed to combine functionality with visua...

READ MORE -

Why Are Globe Valves Key to Efficient Fluid Control? Globe valves play a central role in fluid regulation systems, offering controlled throttling as well as shut‑off capability. Unlike gate or ball va...

READ MORE

русский

русский Español

Español عربى

عربى